A significant contributor to building air leakage is from exterior walls. We have had consistent success with these three methods to address air leakage through walls, which each rely on rigid sheathing as a stable substrate with long-term integrity:

-

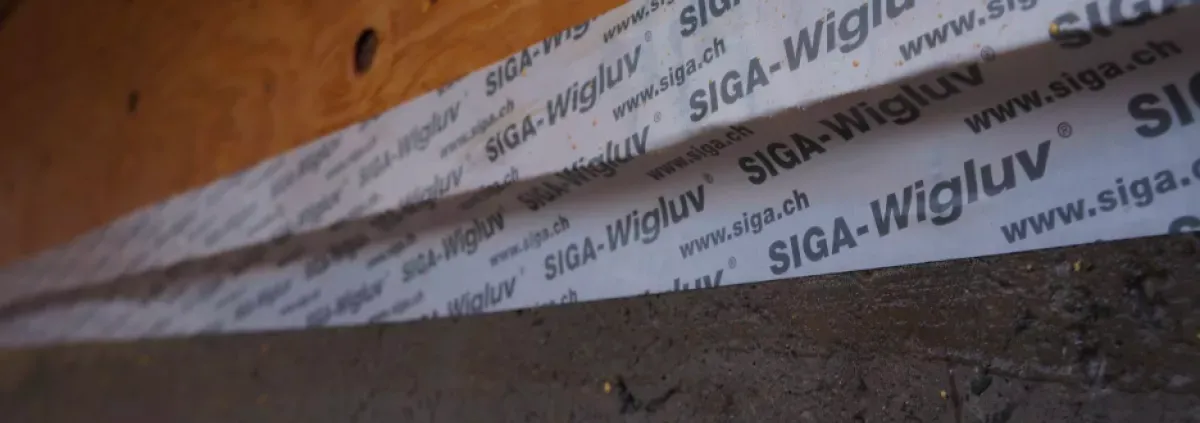

Tape the exterior seams and edges of the plywood sheathing for continuity (in addition to a separate loose water resistant barrier), or

-

Install a fully-adhered weather resistant barrier (WRB) sheet good for both air tightness and bulk water management, or

-

Install a fluid-applied WRB for both air tightness and bulk water management.

See attachment for full document, including recommendations on air tightness testing and materials.

Also download and use the attached Air Sealing Planning template to help in your work.

Adam, I think AeroBarrier has great applications. I like it for 1) retrofits, 2) "code standard" projects that otherwise are just not going to invest in holistic air sealing strategies, and 3) new multifamily projects that sometimes have pretty complicated architecture, and challenging aspects like steel framing, that are just harder to get to a decent level of airtightness. I'm not a fan of it for otherwise high performance projects that really need to just plan and implement a common sense strategy; you can't beat rigid substrates like plywood sheathing, tape and gaskets for long-term performance IMO.

All that said, I can't think of a single one of our projects that have used AeroBarrier! I just looked up notes from a 2018 presentation Neal Walsh and Randy Williams provided to our team (neither of them is shown on AeroSeal's leadership page https://aeroseal.com/leadership/, but maybe they are still affiliated, not sure) and the challenges back then seemed to be:

1. what is stage of project? (rough stage is ideal)

2. where is project? (--> what are travel costs)

3. how many units? (≥50 units ideal to defray costs/economies of scale)

Great question on the emissions of "microplastics" into the environment. I suppose the amount that ends up escaping could be estimated based on estimated volume of cracks filled and knowing how much they started with...