We have executed this slab edge insulation detail a few times now and I wanted to get it out in the world as a simple way to do a seemingly complicated installation.

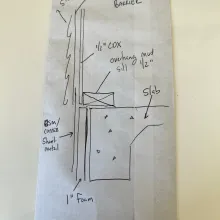

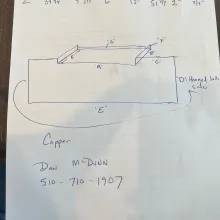

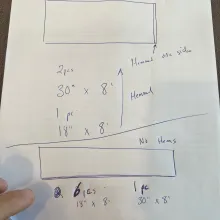

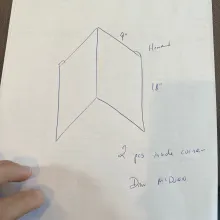

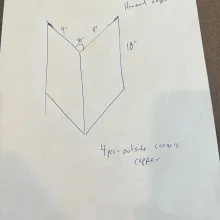

We overhang the mudsill by 1/2" past the concrete slab edge. Add 1/2" sheathing and it creates a nice pocket to capture the 1" slab edge insulation in the same plane as the face of the sheathing. We fabricate sill pans and metal insulation cap (in the last case copper) hem all the overlapping edges of inside and outside corners and attach that to the mudsill with nails. The vapor barrier then laps over the sheet metal. Doing it this way leaves the siding or stucco proud of the slab edge insulation and cap metal in a very elegant way. The insulation and cap metal is behind the siding product and the door pans work the same way as they would over a typical concrete slab without insulation. Section and sheet metal drawings attached.

Thank you Dan - I am pondering your detail and wondering about the termite guard. I guess it can still be there turning down under the sheetmetal

Thanks, Dan McDunn McDunn Construction , this is great. So after installing a few times, is this your new go-to slab edge method?

I like this method as it gives the same basic feel as an exposed slab edge, and it eliminates any weird connections of material or corners. The first one we did we had the foam proud of the siding and had weird returns into door jams and so forth. This detail eliminates all of that clunkiness. This just puts the face of foam in the same plane as the concrete would be in a typical house without slab edge insulation. Copper is sweet but expensive, so if you are going to paint it use bonderized sheet metal for better paint adherence.

The termite shield could still go in behind the sheet metal. Although, the foam is not a food source, and the mud sill in PT, and the adhesives used for the foam and the copper, and the sill sealer below the PT, I believe combine to pretty well eliminate termite risk. Can't hurt though.

Please log in or sign up to comment.